Spring 2013 Project Module | Material Investigation: Concrete

Concrete mixtures can use forms made out of wood, foam and fabric. Fabric forms allowed air passage and required less vibration to set the concrete. Textures of the concrete are directly related to the form used, plastic creating the smoothest. A vacuum formed plastic created a mold for a rope textured tile. Plastic molding was successful for textures, yet has limitations in size and type of texture. Using OSB to create forms with lace texture, smaller forms were successful and larger forms were not.

Final Project | Perforated Coner

A wall is still a wall, even if it is only half there. It contains air, light and concrete. Previously exploring textures lead to a design proposition of concrete as a perforated wall separating inside from outside. A wall that is exposed to weather and can partition a space from the exterior street life. As a wall panel it intrigues a person and is inviting to touch. Holes that are irregular and organic. Light and shadow becomes a strong characteristic of the concrete. Depending if the light is present inside or outside, the face will seemly change shape. A building in Mexico has a strong street and indoor separation. How can these heavy walls be softened?

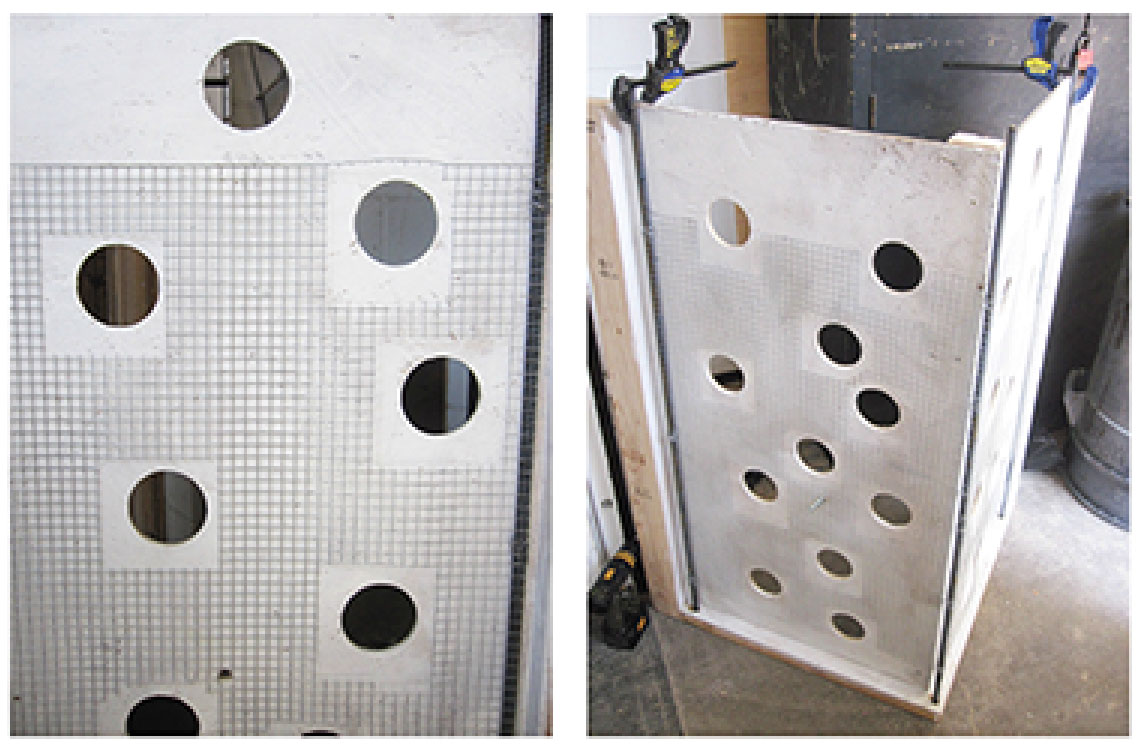

Form: Drilled three inch holes offset into OSB and voided space with water noodles covered in packaging tape. Inside was primed and used reinforcing bar and wire fabric for reinforcement.

Rough OSB texture compared with smooth, plastic-tape texture

Outside Review

Altering the Mexican street facade

Pre-Destruction